POINT Since excavation by blasting is difficult at sites near a residential area, it is necessary to excavate by machine. However, excavating hard rocks takes time. Hence, Tasisei Corporation and MITSUI MIIKE MACHINERY jointly developed a machine that could excavate even hard rocks freely. Consequently, it became possible to efficiently perform excavation even in areas with hard rocks.

Challenges prior to implementation

Efficient construction calls for a machine that could also excavate hard rocks

In recent years, there has been a growing number of cases where tunnel construction is carried out near residential areas, roads, railway lines and important facilities. In such cases, contractors undertaking the construction work should, in principle, proceed with the construction while giving due consideration to the surrounding residents and the environment. The blasting excavation method using gunpowder and the breaker excavation method that generates a striking sound, among other methods that are used in ordinary tunnel construction, are designed to reduce vibration and noise. Even so, however, there are quite a few cases where such methods are not accepted and cannot be employed.

Taisei Corporation, which plays a role in building social infrastructure in Japan and overseas through its construction and civil engineering businesses, was also faced with this problem. When blasting excavation cannot be used in ordinary tunnel construction, work is carried out using a free-section excavator. However, there are cases when the ground contains hard rocks with an unconfined compression strength exceeding 50 MPa, and in such an area with hard rocks, the excavation capacity of the free-section excavator in fact gradually declines, making it difficult to avoid cost increases and a lengthening of the construction period.

In order to shorten the construction period, Taisei Corporation saw the necessity of excavating with a machine and initiated the development of a machine that could excavate even hard rocks that require pressure of 100 MPa or more, which had been difficult to excavate with conventional machines. We decided to develop an excavator adopting a disc cutter.

Products

Development of a machine that could freely excavate even hard rocks requiring a pressure of 100 MPa or more

Since Taisei Corporation had developed the MM 130R hard rock excavator, which used a disc cutter, jointly with a U.S. construction machine manufacturer Robbins 20 years before, the firm preferred to continue with this hard rock excavator technology. However, given that MM 130R was an ultra-large machine, there was a need to not only downsize it to meet the needs of the field, but also make it more user-friendly, design it so that assembly and disassembly can be shortened, and install functions utilizing the latest technology.

MITSUI MIIKE MACHINERY was selected as a partner in the development of a new hard rock excavator, based on its experience in the use of free-section excavators in tunnel excavation and its extensive technology for manufacturing mine excavating machinery. The two companies proceeded with the project under a joint development approach.

An important aspect of this project was the enhancement of excavating capacity. The new hard rock excavator adopted a method of using a high-pressure rotary disc cutter to create cracks, which were connected to each other to break the rocks and move forward. This machine has made it possible to freely excavate hard rocks requiring a pressure of over 100 MPa. Meanwhile, in tunnel construction, after conducting excavation to a certain extent, the process of carrying out dirt and sand and fixing the natural ground is performed before going back to the excavation work. To ensure that excavation can be resumed from a proper position, we installed an automated system that could guide the machine to return to the proper position. By simply installing the excavator in the prescribed place, excavation could be automatically resumed. In addition, we designed the machine so that the shape of the face is always maintained in a spherical shape to stabilize the face and increase safety at the work site.

Post-implementation benefits

Enabling excavation of hard rocks requiring a pressure of over 100 MPa at a pace of about 15 m3 per hour

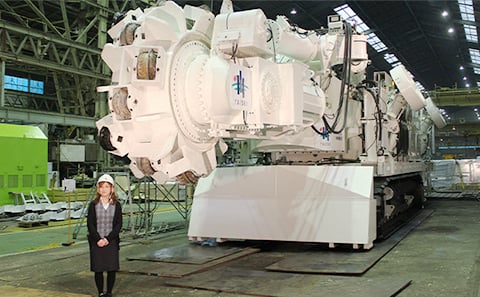

The new hard rock excavator TM-100, which was completed after a development period of about two years, demonstrated its ability to excavate simulated rock mass requiring a pressure of 100 MPa in an excavation performance test. In addition, when excavating hard rocks requiring a pressure of 80 MPa or more, the machine demonstrated twice as much excavating capability as that of conventional machines. Furthermore, replacing the disc cutter with a pick made it possible to excavate soft rock areas.

Taisei Corporation launched this powerful TM-100 at the construction site of the Kawanishi Tunnel on the Shin-Meishin Expressway. Since the site was particularly close to residential areas, and the ground was composed of rocks of various types and levels of hardness, the construction work was expected to be difficult with conventional excavators. However, thanks to TM-100, excavation even of hard rocks progressed efficiently.

Recognizing this achievement, the project received the 2016 Innovative Technique Award from the Japan Society of Civil Engineers and the 9th Engineering Incentive Special Award from Engineering Advancement Association of Japan. This must have been a good opportunity to promote the development capabilities of both companies within the industry.

As the TM-100 model was still larger than the conventional machines and the number of sites where it could be operated in Japan was limited, its operation, unfortunately, ended after having been adopted for only one site. However, the special knowledge on new functions and systems gained through this development can be used in the development of other equipment.