Power Transmission

Electric motor/Power Generator

Our electric motors and power generators are custom-made to meet the diverse needs of customers by leveraging our proven technological capabilities underpinned by 100 years of experience.

Overview

The Company produced its first electric motor in 1910. For over a century since then, we have built a strong track record in a variety of fields, including material handling machinery, excavating machinery, and construction machinery derived from mining machines, as well as fans and pumps. In recent years, we have also been making efforts to reduce environmental impact. We developed a top-runner motor that meets energy conservation standards and a power generator for a small hydroelectric power generation system, which is attracting attention as a green energy source. Our aim is to contribute to the creation of an affluent society capable of sustainable development by reducing CO2 emissions and taking other steps.

Features

Feature 01Top runner motor and low starting current

Our motors, while satisfying the IE3 efficiency standard, achieve a low-starting current thanks to the our proprietary three-phase cage technology that enables direct starting even in cases that conventionally required a start compensator. This has resulted in a significant lowering of the cost of equipment at the receiving end as well as a reduction in CO2 emissions due to energy conservation through enhanced efficiency. It is also possible to replace an existing general-purpose motor with an IE3 motor without changing the equipment on the receiving side.

Feature 02Optimum torque setting according to the load

The torque of the load varies depending on the equipment that uses the motor. We accommodate customer needs by proposing the optimum output and torque, such as a decreasing torque for fans and pumps, a constant torque for conveyors, and a heavy load torque for excavating machines. By so doing, we make it possible to optimize and downsize the entire equipment, which leads to reducing the cost of the equipment as a whole.

Feature 03Compatible with a wide variety of models

We have a history of production in a variety of environments, specifications, and shapes achieved through leveraging our technologies derived from mining machines.

Even when specifications cannot be fully met with a general-purpose product, we can manufacture custom-made products according to the purpose and application.

Feature 04Promoting downsizing of devices on the receiving side

The starting current is approximately 4 times the rated current, and this is significantly smaller than that of a general electric motor which is 6 to 8 times the rated current. This enables resource-saving and cost reduction in terms of the following:

- Reduces the volume of power distribution equipment

- Output of the motor can be increased even in existing facilities

- No need for starting via the reduced voltage method (Korndorfer or reactor), making the device compact

- Low starting current reduces the cable size for long-distance wiring, etc.

- Use of a starting device can roughly double the starting current equivalent to that of the winding type

- Low starting current is advantageous for preventing flicker

Removal of the Korndorfer starter plate as a result of replacing the Korndorfer start with the direct-on-line start

Removal of the Korndorfer starter plate as a result of replacing the Korndorfer start with the direct-on-line start

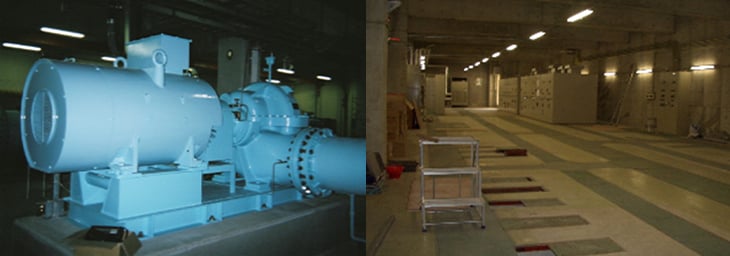

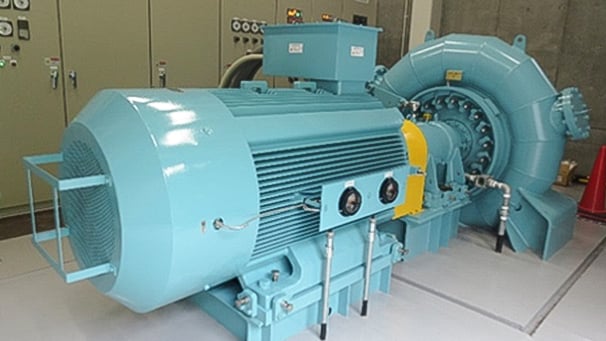

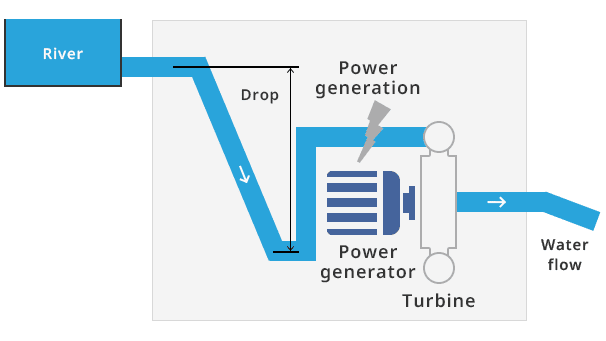

Power Generator

We manufacture power generators to produce electric power from natural energy sources such as river water. Our power generators are specifically designed for each power station in line with the energy of the river and the environment of the facility and can be operated in a highly efficient manner with a high power factor.

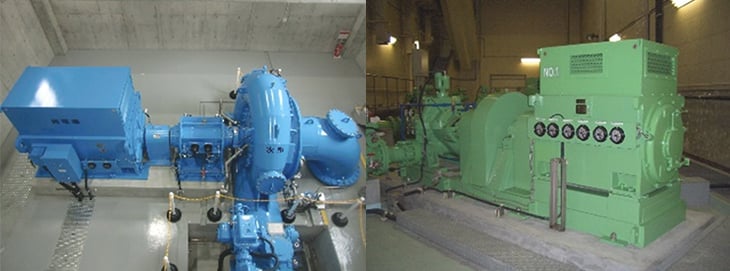

Examples of Products Manufactured

Electric motors

-

Water-cooled geared motors for shield excavators

Water-cooled geared motors for shield excavators

-

Motors for air blowers in a purification center

Motors for air blowers in a purification center

Low starting current + high efficiency characteristics -

Voltage flicker suppression-type high-efficiency electric motors for dam water intake pumps

Voltage flicker suppression-type high-efficiency electric motors for dam water intake pumps

-

Multipole high-efficiency electric motors for air blowers for tunnel ventilation equipment (air exhaust machine)

Multipole high-efficiency electric motors for air blowers for tunnel ventilation equipment (air exhaust machine)

-

For underwater pump

For underwater pump

-

For vertical pump

For vertical pump

-

For earth auger

For earth auger

-

For built-in use

For built-in use

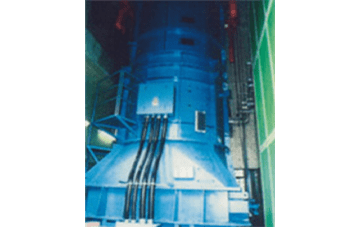

Power Generator

-

For small hydroelectric generator (Francis turbine)

For small hydroelectric generator (Francis turbine)

490kW-8P -

Example of hydroelectric power generation

Example of hydroelectric power generation

Delivery to local governments, etc.

The characteristics of our electric motors—low starting current and ultra-high efficiency exceeding JIS standards—eliminate the need for a starter panel. This contributes to significantly lower costs achieved through reducing not only construction costs (equipment cost and electrical room area) but also running costs.

In addition, since our power generators make it possible to lessen environmental impact by cutting CO2 emissions, they have been adopted by many municipalities that are implementing initiatives to reduce total CO2 emissions.

-

Motor for intake pump at pump station

Motor for intake pump at pump station

-

Booster pump station

Booster pump station

-

Road immersed tunnel (for tunnel ventilation equipment)

Road immersed tunnel (for tunnel ventilation equipment)

-

Construction for tunnel ventilation equipment

Construction for tunnel ventilation equipment