Indoor Storage System

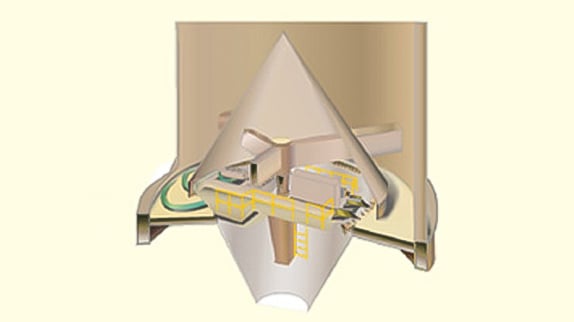

MDM-RR type silo storage system

This system was developed exclusively for storing gypsum and has high functionality and maintainability.

Overview

The rotating center of the blades is located at a position eccentric from the center of the silo, and the blades are rotated while revolving to cut out the materials handled and discharge them to the lower conveyor. The silo body can be made in straight-drum form, which avoids bridging.

| Applications | Storage of gypsum | Materials handled | Gypsum |

|---|---|---|---|

| Deliveries | 3 cases (domestic power plants) | Capacity | Silo capacity: 1,000 to 1,500m³ (1,000 to 1,500t) Discharge capacity: 40 to 500m³/h (40 to 500t/h) |

Features

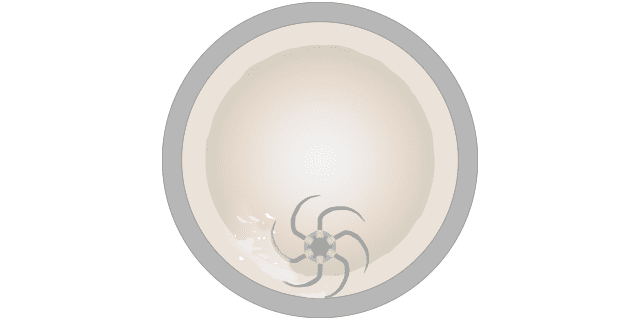

Feature 01Preventing materials handled from sticking

Since old gypsum does not remain even if the silo is not completely emptied, it can effectively prevent materials from sticking. The MDM-RR type discharge equipment safely and stably discharges self-hardening gypsum by revolving its main body and rotating the attached blades.

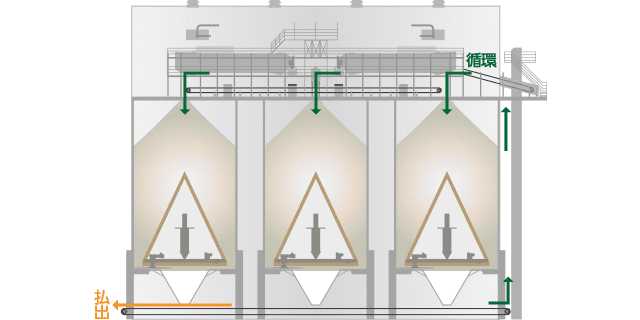

Feature 02High functionality developed exclusively for gypsum

The storage system is combined with a circulating conveyor to prevent sticking of gypsum and heat generation caused by long-term retention.

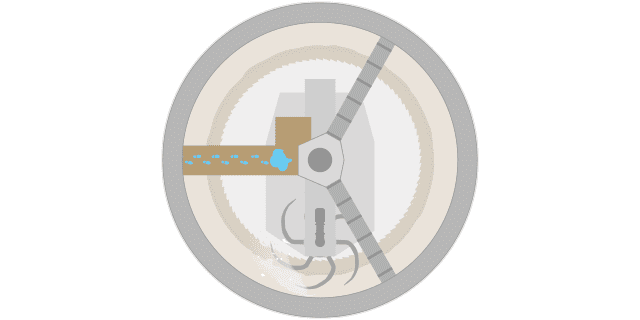

Feature 03Highly user-friendly maintenance

Even with gypsum remaining in the silo, all equipment can be accessed directly from the outside through a dedicated, completely isolated support passage.

-

First-in, first-out operation avoids congestion and is less prone to spontaneous combustion

First-in, first-out operation avoids congestion and is less prone to spontaneous combustion

-

Eco structure that offers excellent airtightness and prevents scattering of dust

Eco structure that offers excellent airtightness and prevents scattering of dust

-

Construction of automatic operation system contributing to labor saving

Construction of automatic operation system contributing to labor saving

-

Proposing the optimum silo system based on materials handled and storage capacity

Proposing the optimum silo system based on materials handled and storage capacity

Mechanism

System overview of discharge equipment